Сверхтоннажный Электроприводной Погрузчик XCMG XC9350 (CE)

Техническая документация

ОПИСАНИЕ

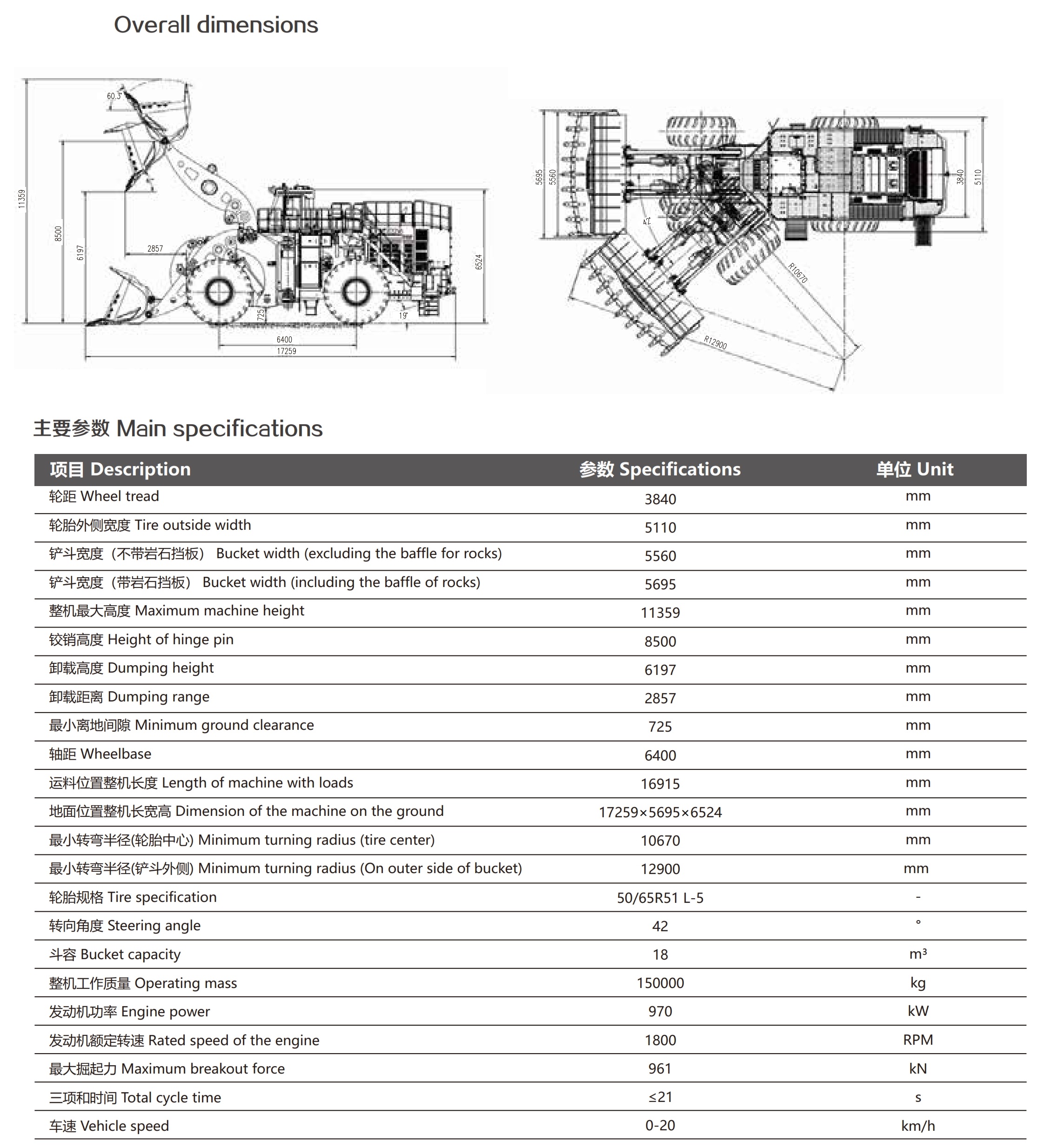

ХАРАКТЕРИСТИКИ

Сверхтоннажный Электроприводной Погрузчик XCMG XC9350

XC9350 is the self-innovated four-wheel independent electrical-drive loader with operating capacity up to 40 tons, which now is the loader of the largest tonnage refreshing the record of XCMG LW1400KN in the domestic market. The independent development of critical technology makes us the leader of super-large-tonnage loaders by breaking the monopoly of international competitors. The machine is the optimal option for XCMG 110-200-ton mining trucks featuring multiple characteristics including long service life, low maintenance cost and high reliability, etc., and applicable to various conditions including large strip mines, loading by mining trucks, and short-distance transportation, etc.

AC-DC-AC high-voltage electrical-drive system of high efficiency and quick response, featuring special functions of anti-slip, limp home mode, and automatic protection, etc.

Hybrid power and energy recovery, with effective recycling of energy generated by integrated electro-hydraulic braking (EHB) to drive the wheel rim motor and minimize the abrasion of mechanical braking.

XCMG core technology of «Intelligent electro-hydraulic proportional control system + electrical positive-flow hydraulic system + electrical load-sensing handle-steering system» to realize accurate and efficient compound actions during operations including loading, driving, and steering, etc.

Intelligent man-machine interaction system featuring real-time, safe, easy, and fast monitoring and diagnosis of operation as well as the complete safety protection system.

Structure parts

Luxurious operating environment

The structural parts are made of cold high-strength structural steels, with high-strength c for critical stress-bearing parts, featuring high loading capacity for torques and impacts multiple working conditions.

Unique working device with dual-rocker arm, with the moving arm and bucket m high-strength and abrasion-resistant structural steels for severe conditions with variable

Drive system

The hub reducer assembly consisted of multiple-stage planetary wheels featuring a high ratio and large torque.

Maintenance-free drive shaft with high anti-torque capability and reliable transmission.

The high reliability multi-functional combination instrument equipped accurately monit running status of the engine and accurately reads the malfunctions of engine and trans via CAN bus communication technology. With sound-light alarm and indication, the LCD accurately displays the running status of the whole machine.

High energy-conservation and efficiency

Perfect matching of the engine, generator and wheel rim motor to maximize the efficiency and minimize

AC-DC-AC electrical drive system with high efficiency, advanced control technology, and fast response, as well as more than 20% of fuel conservation, compared with other hydraulic-drive loaders with the same capacity.

The AC squirrel-cage type motor is featuring high reliability, low maintenance ratio and large output torque, etc.

The electrical positive-flow hydraulic working system, associated with constant-power control technology, has improved the energy conservation, fast response, and controllability of the hydraulic system and the efficiency of the combination process.

The electrical load-sensing handle-steering system can realize the accurate control of the machine and improve the comfort of the operator.

The unique working device with the dual-rocker arm is configured with the limit sensing mechanism with angle memory, featuring functions including elevating limit, automatic leveling, etc. to ensure accurate limit, reduce the impact and prevent repetitive operations during elevation and unloading. It can not only minimize the working intensity but also improve the operating efficiency of the machine.

Hybrid power and energy recovery, with effective recycling of energy generated by integrated electro-hydraulic braking (EHB) to drive the wheel rim motor and minimize the abrasion of mechanical braking.

All-new integrated and supercharged driving cab, complying with the requirement of

ROPS&FOPS specified in relevant ISO standard.

Adjustable and air-suspension seats with high backrest featuring strea and shock-absorption, configured with seat for co-driver.

The operating data, failures, and alarms will be indicated on the LCD array and the control instruments.

The silicone oil shock absorbers are adopted to connect the cab with realize the flexible vibration transmission and remarkably reduce the jit cab.

The high power heating and air conditioning system with intelligent control and the pressurized cab provide you with a super-quiet a comfortable operating environment with appropriate temperature.

Noise to the operator 75dB.

Safety braking

Electrical retarder brake: It is controlled by the accelerator pedal which can stop the machine without applying the mechanical braking.

Service brake: The braking disc of hydraulic braking motor. Each drive motor is configured with one braking disc and one braking caliper to ensure braking on fixed points of the machine.

Parking brake: It is the spring braking with the braking disc of hydraulic release drive motor, that each motor inside the rear drive axle housing is configured with one parking brake.

The real-time collection of temperature and pressure data will be done by the sensors in the tires for safety operation.

Reversing camera system

The reversing camera system is equipped to reduce the rearview blind zones and improve the working safety.

Maintenance access

45° automatic ladder with three-point support for the operator with safety and comfort.

Left and right aisles with emergency exits with easy access.

The machine is configured with multiple platforms and points for maintenance and the hood is designed with various rotary structures for easy maintenance and limited duration of shutdown required.

Centralized and fast filling and sampling

Quick filling of fuels, engine oil, and hydraulic oil with high efficiency.

The centralized sampling of transfer case gear oil, engine oil, and hydraulic oil with easy operation.